PID Micromeritics

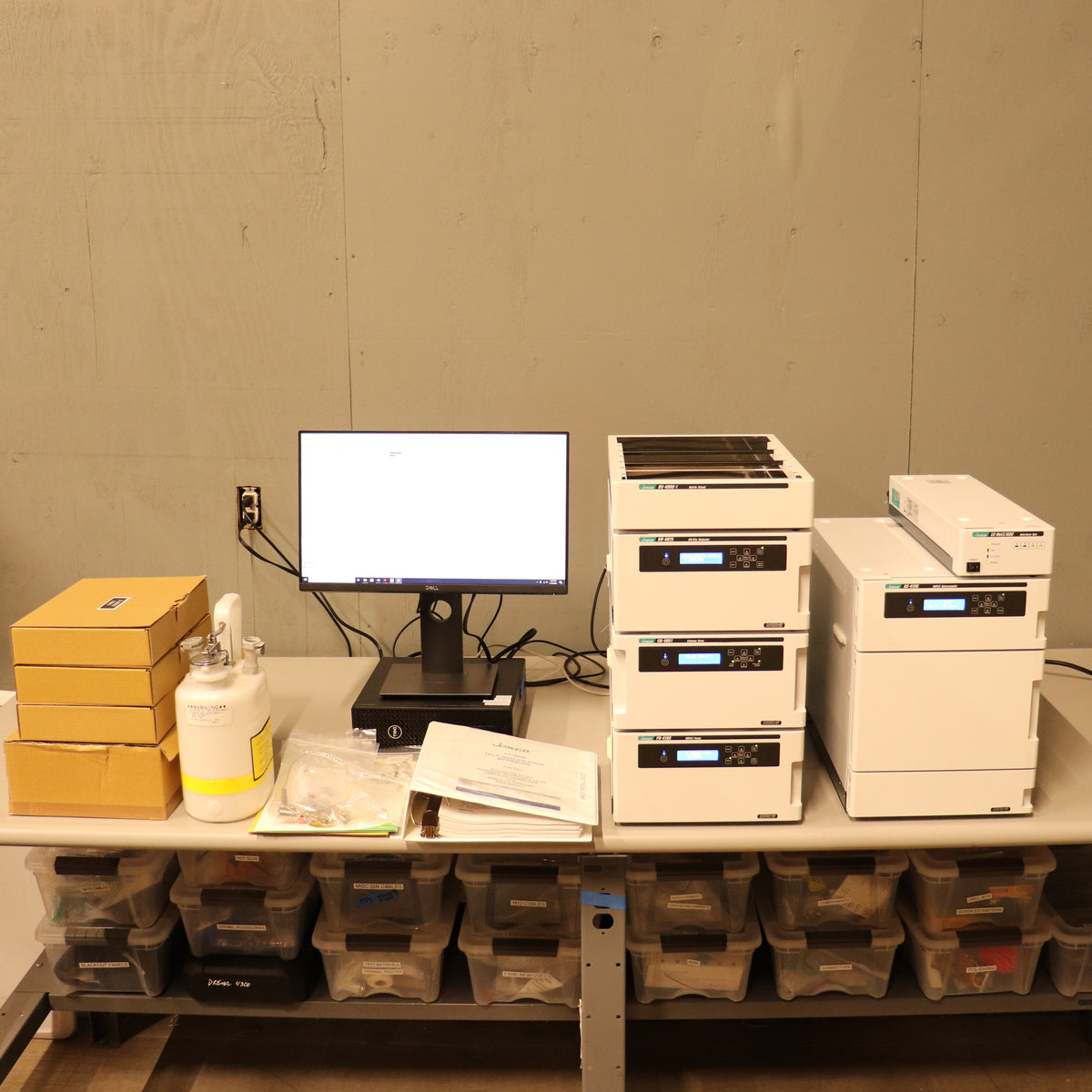

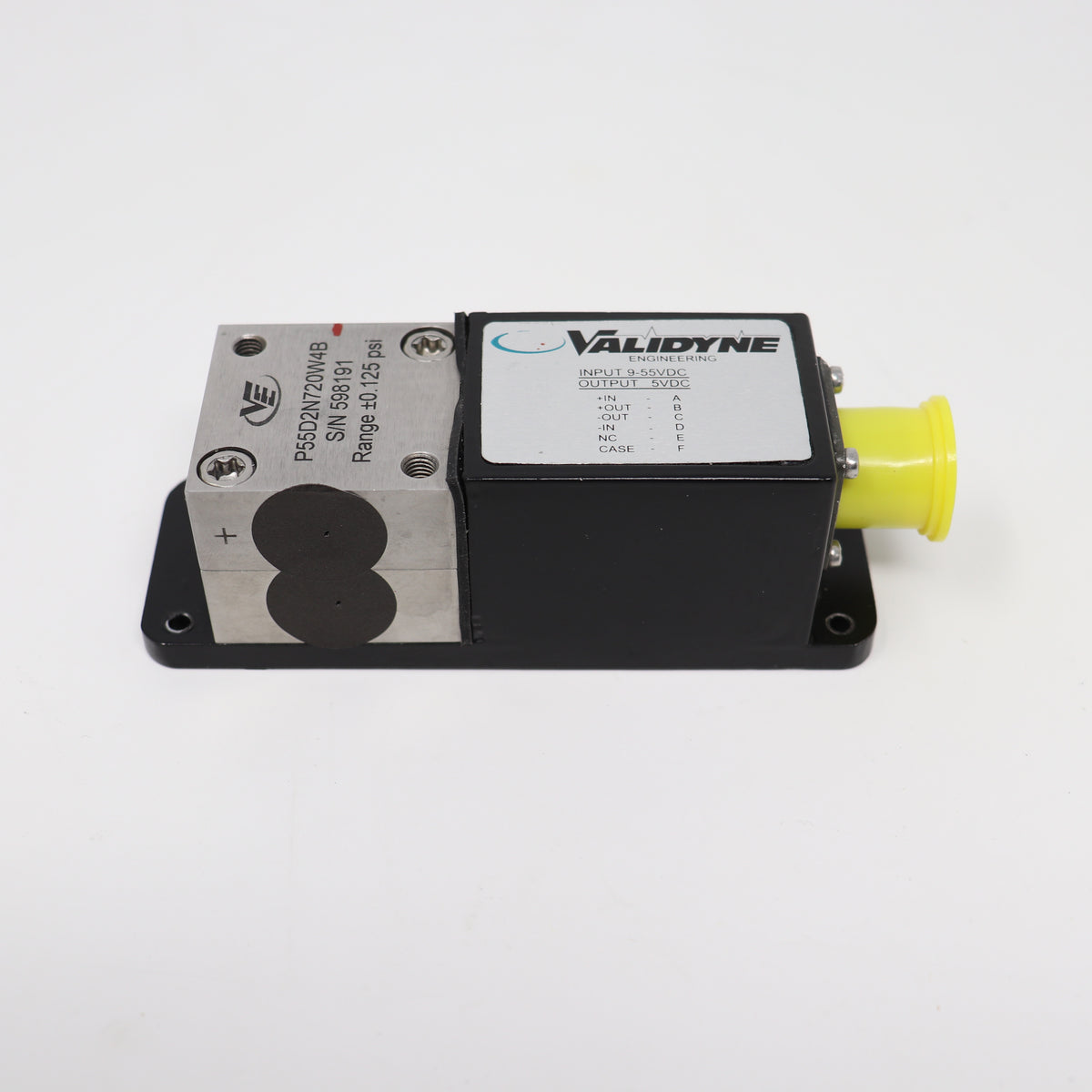

PID Micromeritics Microactivity Effi Automated Catalytic Microreactor Analyzer MAE

PID Micromeritics Microactivity Effi Automated Catalytic Parallel Microreactor Analyzer

Model: Parallel MAE w/ Automatic Gas sampling System

MFG Date: 2020

Includes:

- Standard features, plus

- External automatic gas sampling system - 10 position

- Microactivity Effi System w/ (2x) SS304 Furnaces currently configured for parallel reactors. Furnace Max Temp 1120°C. Reactors not included.

-

(6x) MFC's (12x Total, all external) for each reactor, currently configured for the following gas types: H2, N2, C2H6, C2H4, N2, Air.

- Hot box heating element for a max continuous operating environment of 180°C, or up to a peak of 200°C

- (4x) six- way valves. Valve 1 and 3 set w/ two positions used to bypass the reactor and send reagents directly to the phase separator and then to the gas outlet. Valve 2 and 4 set w/ two positions used to bypass the phase separator and send reagents directly to the to the gas outlet.

- (2x) PCV's (pressure control valves) relative to 100 bar

- (2x) Liquid/ gas separators w/ peltier cells for temp range control between 5°C and 60°C.

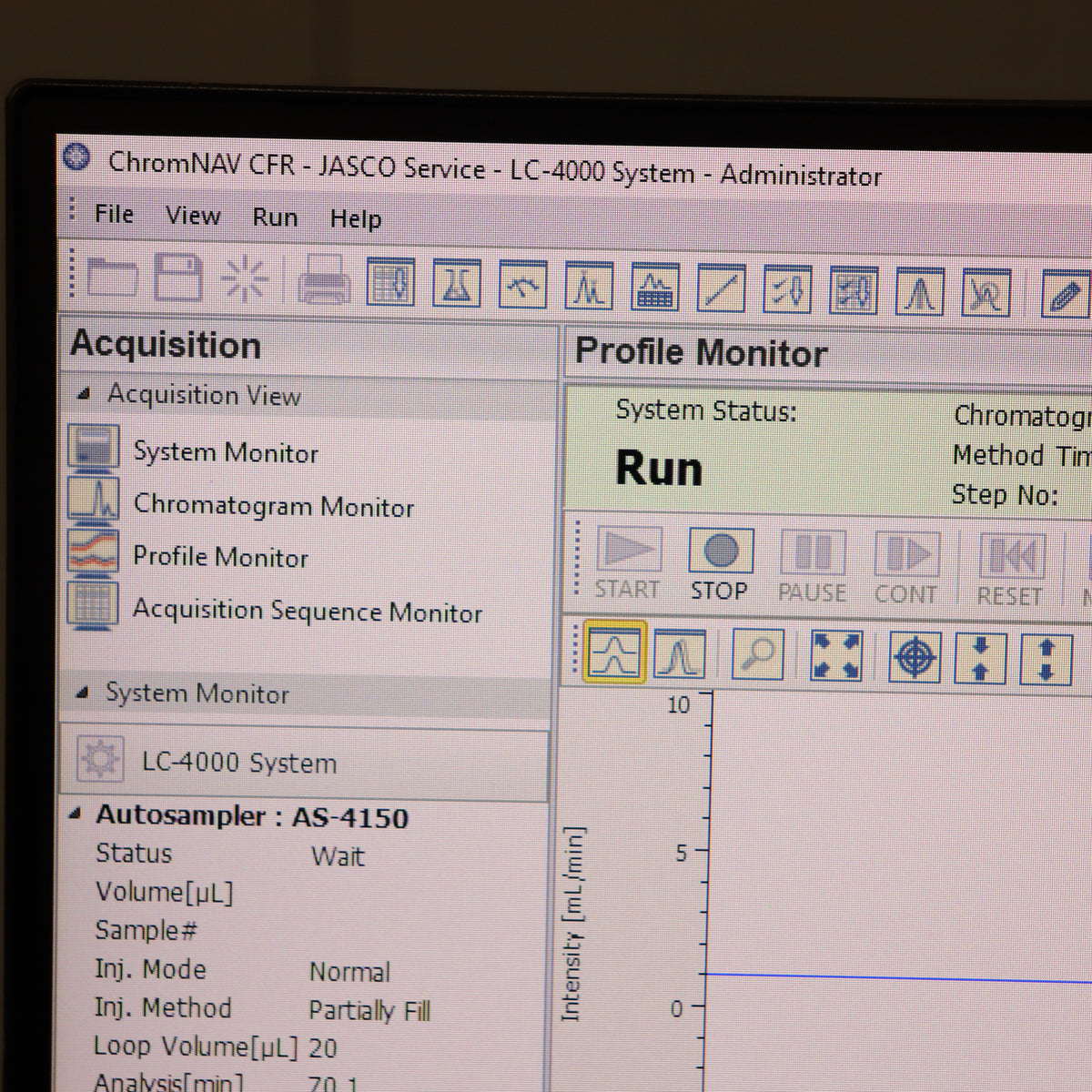

- AIO PC w/ Process@ software

- Manual, Technical specs doc, Software CD's, misc cables

Condition: Used, tested in good working condition. Login credentials w/ passwords will be provided. Includes Manuals, software keys, recovery disc, and misc cables

Description:

The Microactivity Effi reactor is probably the most advanced worldwide modular laboratory system for measurement of catalytic activity and for the study of the yield and kinetics on chemical reactions.

PID Eng&Tech, is a worldwide leading company at sector of Microreactors for Catalytic studies. This instrument has been developed as a standard unit that can be adapted to whatever performance is needed for catalytic testing through different configurations and options.

The Microactivity Effi is a compact reactor that is completely automated. It is equipped with cutting-edge process control technology in the market. This enables the user to program a series of experiments from the computer, even on the network, and obtain real-time results with the highest degree of reproducibility and accuracy.

This equipment has been designed to save time and resources at both, catalyst development stage and factory report process during catalyst screening.

WORLDWIDE SHIPPING AVAILABLE

Worldwide Shipping

30 Day Guarantee

Secure Checkout