Sartorius Stedim

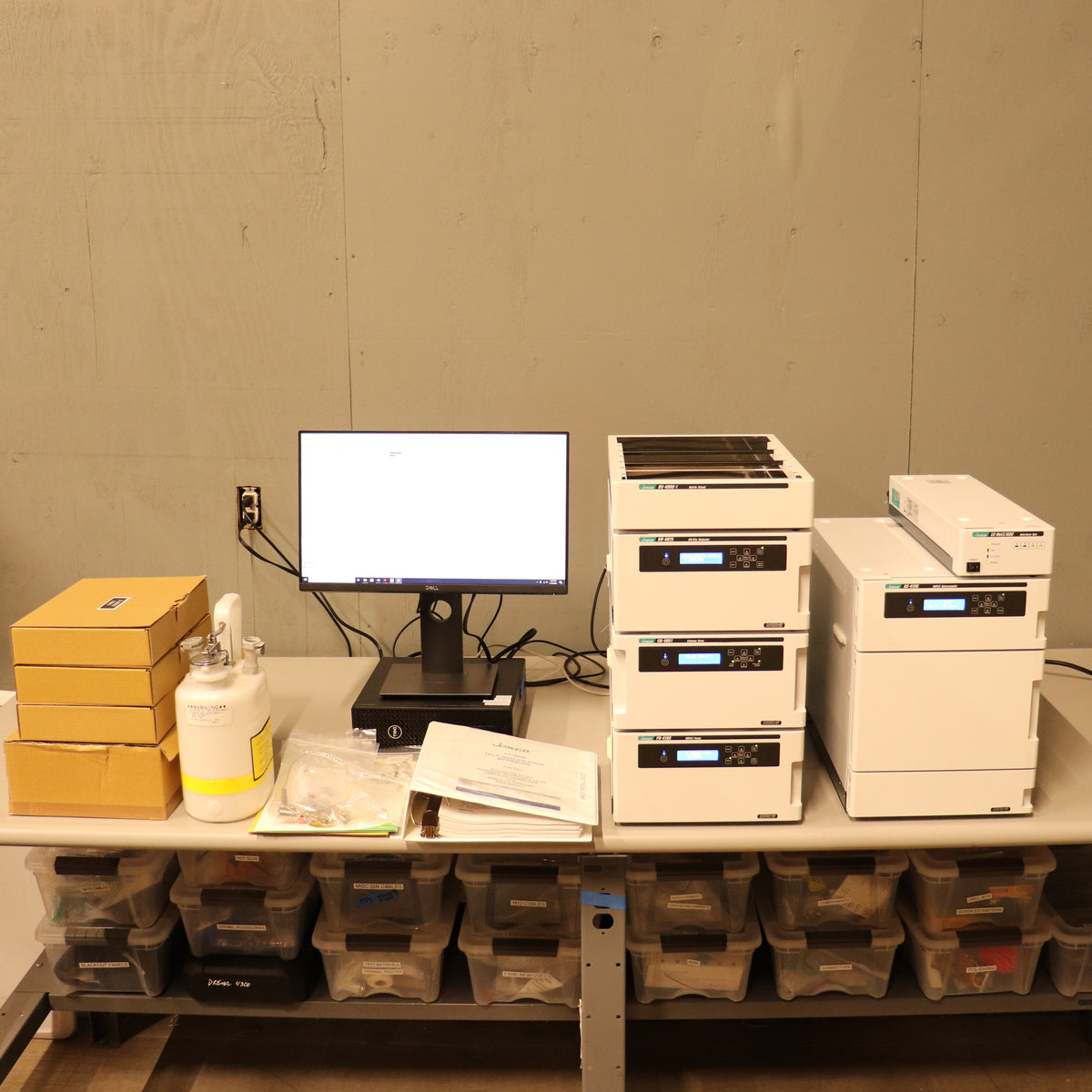

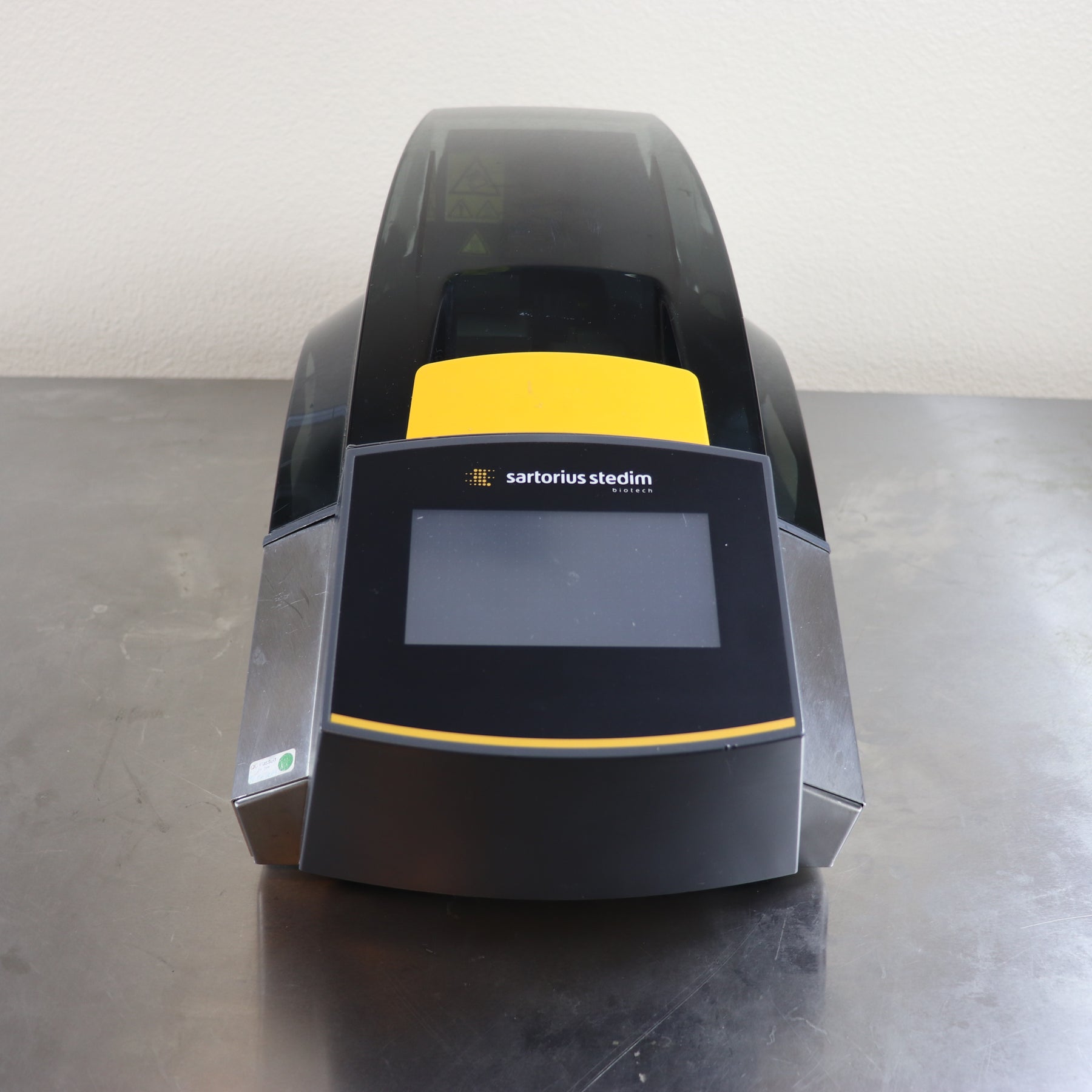

Sartorius Stedim Biowelder TC Total Containment

Sartorius Stedim Biowelder TC Total Containment

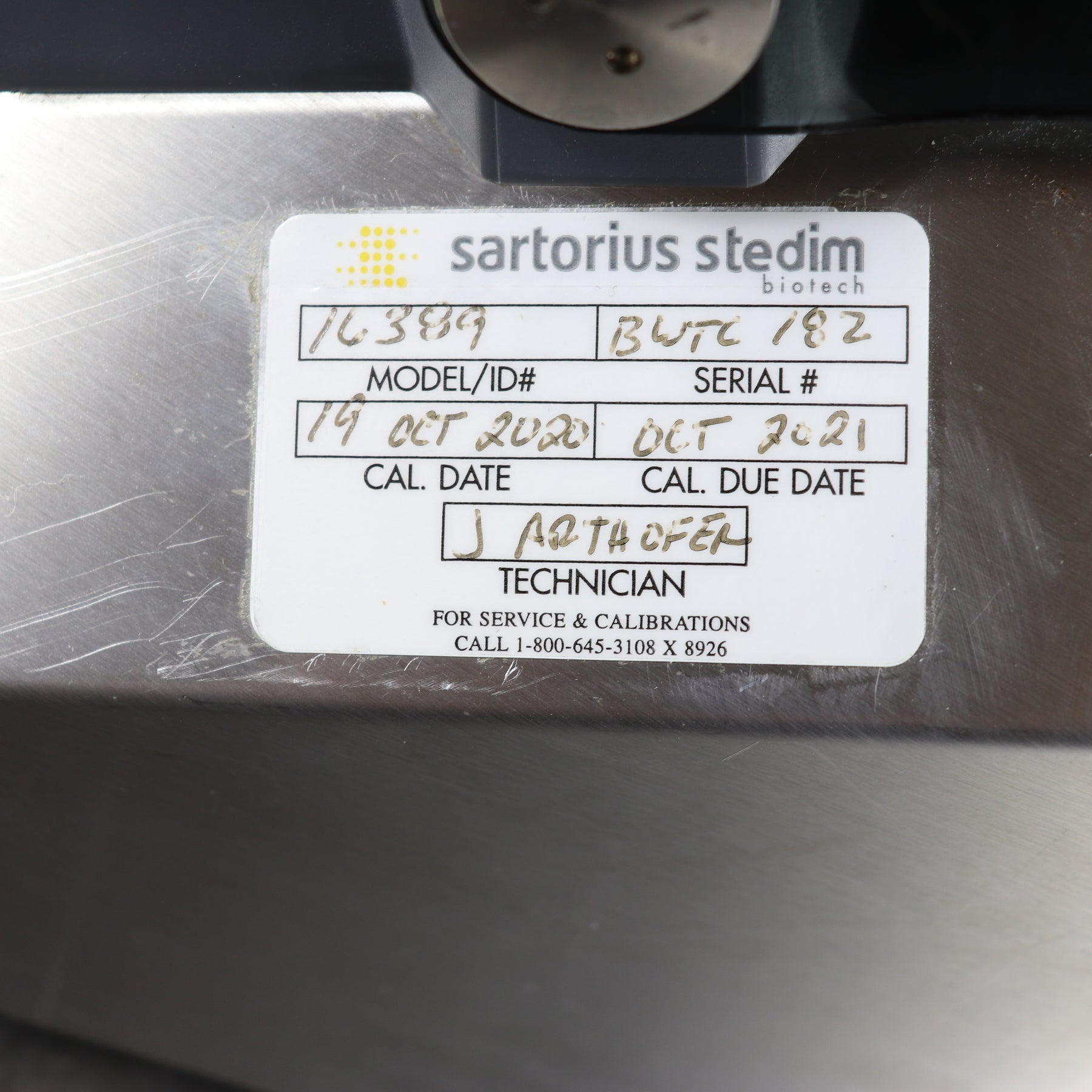

Condition: Used, in good working condition. Units last had PM between 2018-2020 depending on the unit. Units have 1109,1128, 1378 weld cycles.

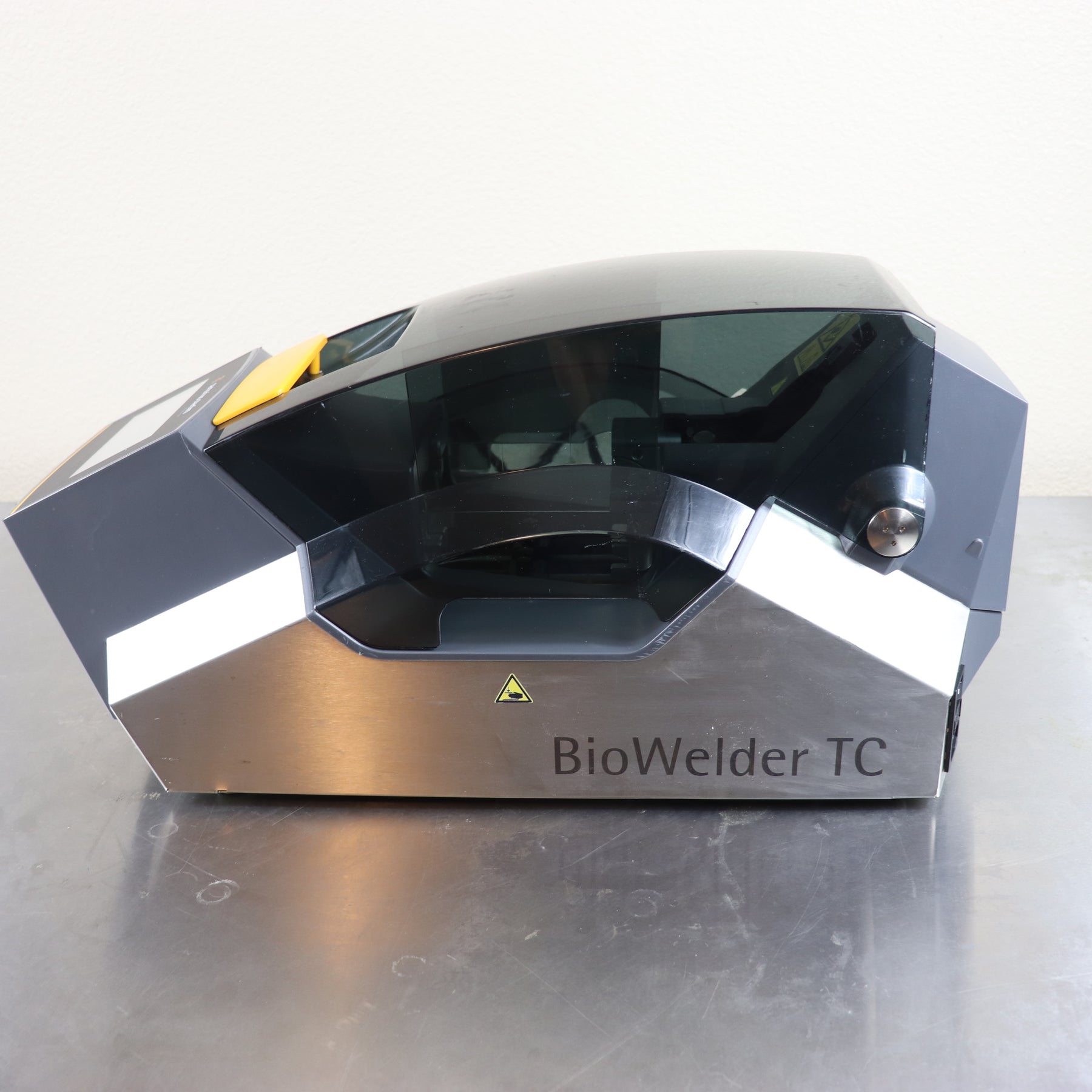

Description: The BioWelder® TC is a fully automated welder for connecting thermoplastic tubing in a sterile welding operation. This new innovating technology allows sterile connection of dry or liquid filled TPE tubing up to 1 inch outer diameter. The BioWelder® TC produces TPE tubing welding through a thermal connection and ensures an extraordinary level of stability and guarantees a sterile connection.

- Liquid filled tubing from 1/4' to 1' OD: flexible, multiple additions via the same tubing line

- Fully automated device: easy to use

- Standard programs: ready to use for C-Flex® 374,Tuflux® TPE, AdvantaFlex®, SaniPure® and PharMed® tubing (not for 1/8' x 1/4')

- Improved design (including device holder | color coded): ergonomic

- Extensively qualified: Safe and robust sterile welding connections

- Extremly short welding time: fast connections from 1,5 up to 2,5 min

The BioWelder® TC is used to connect thermoplastic tubing such as C-Flex® 374, Tuflux® TPE, AdvantaFlex®, SaniPure® BDF™ and PharMed® BPT, used on disposable bags or bag assemblies within all biopharmaceutical manufacturing processes.

Quantity: 1 unit per purchase

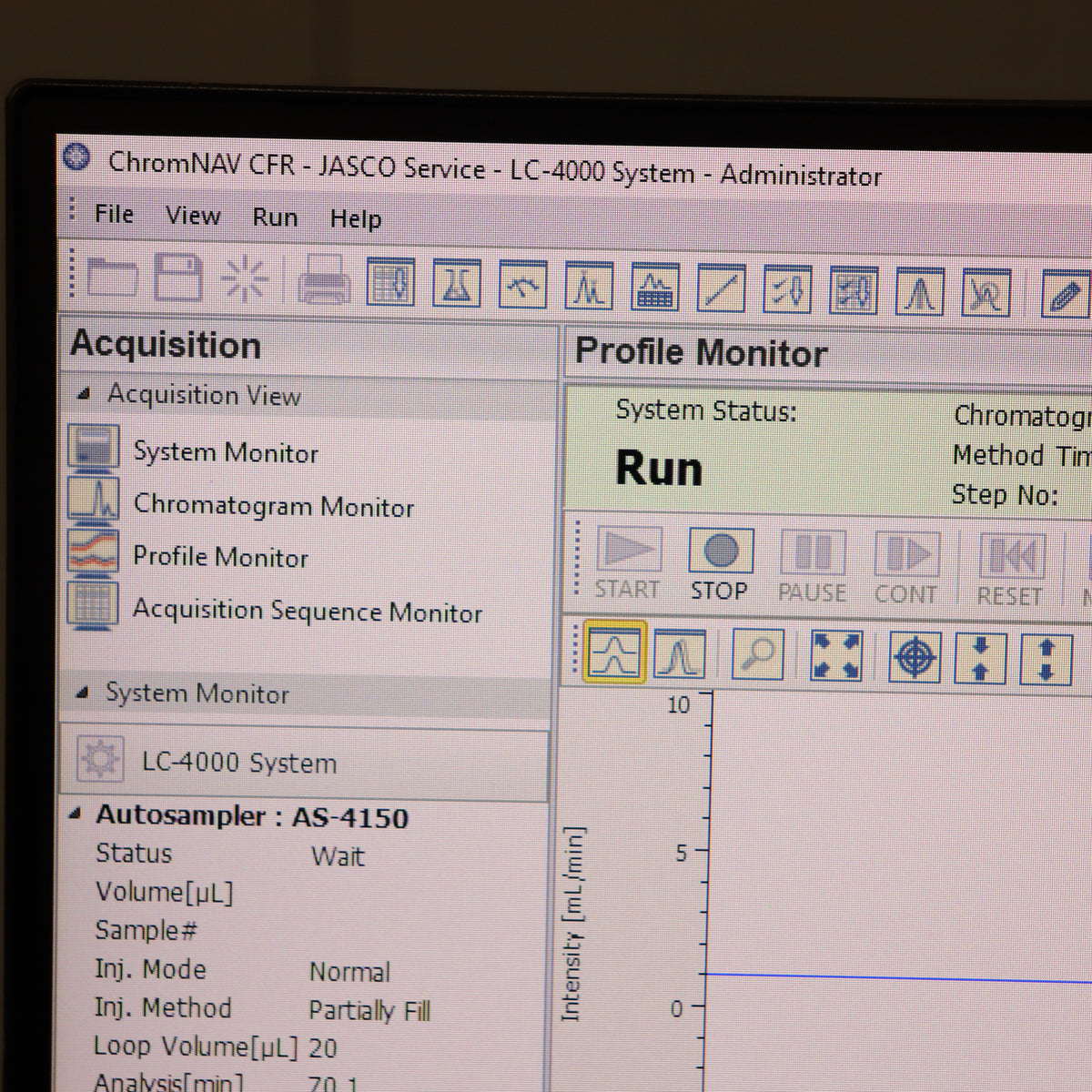

Working Principle

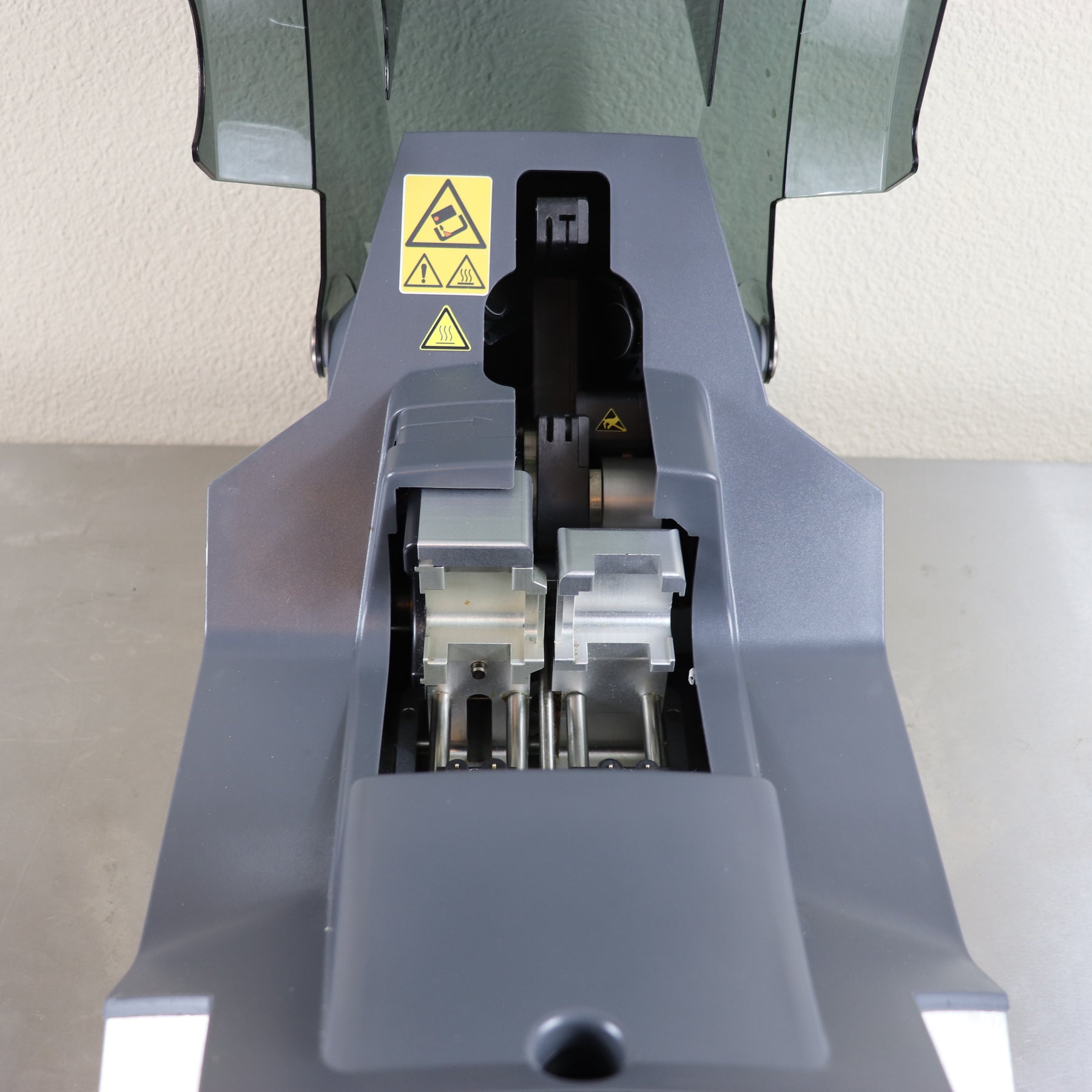

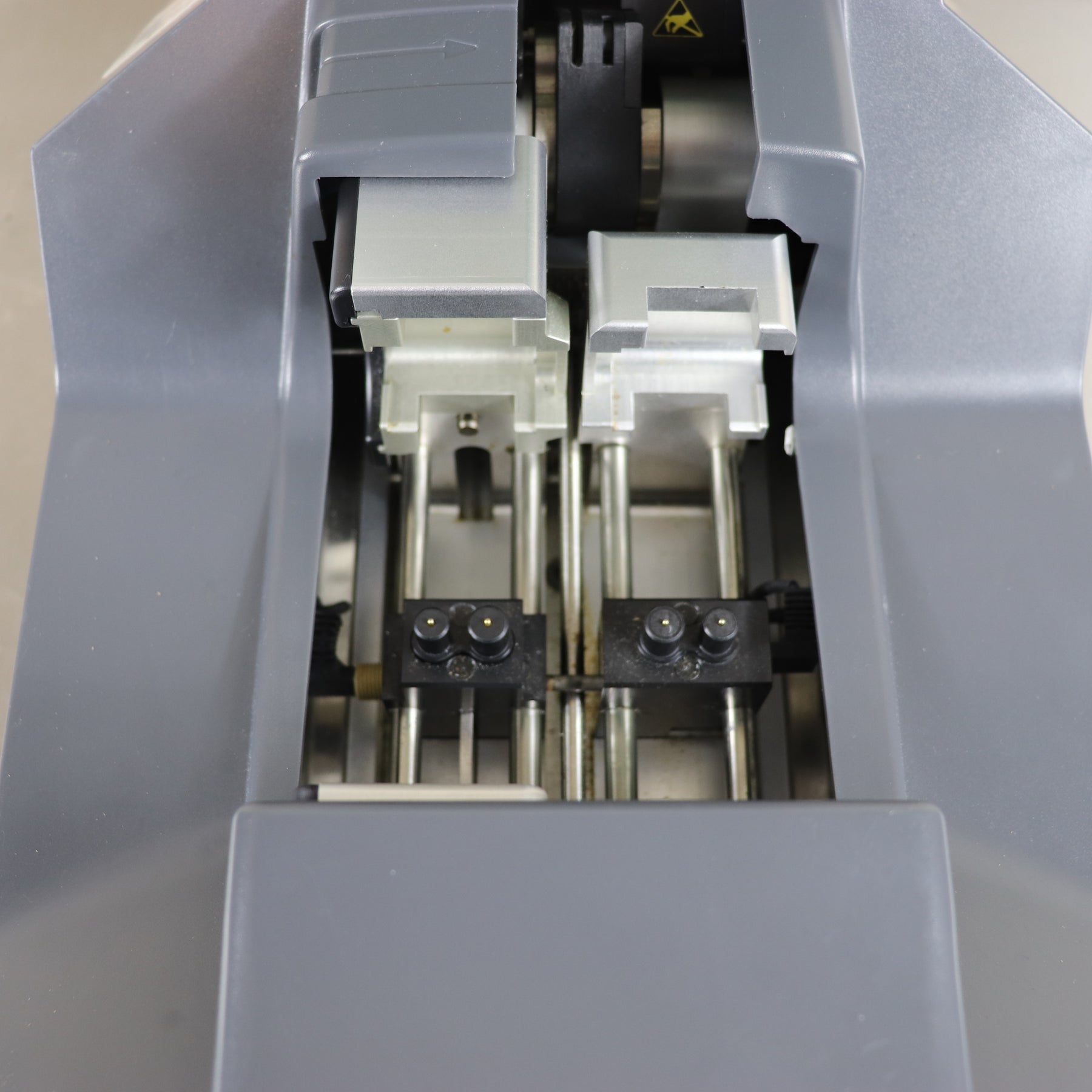

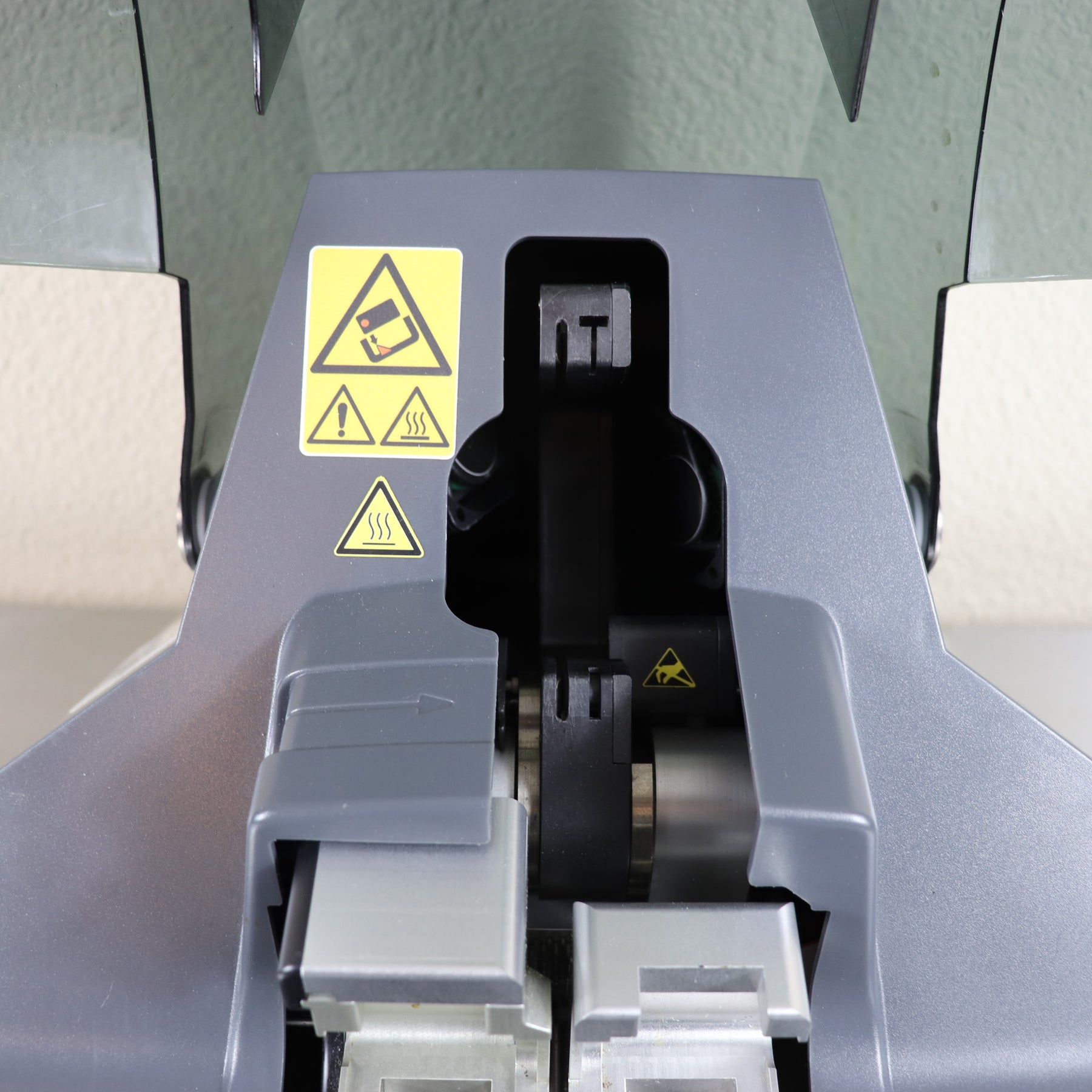

The tube holders, the disposable blade and the tubes are inserted into the BioWelder® TC. The tube welding process is fully automated and is started via the touch screen LCD. The blade is first heated up for depyrogenation and cooled down to the welding temperature. An infrared sensor monitors and controls the blade temperature during the entire welding process. When the blade reaches the welding temperature, the blade cuts the tubes and the new fluid path is welded together.

Applications

BioWelder® TC can weld either dry or liquid-filled tubing in non classified and classified environment while maintaining product sterility.

Worldwide Shipping Available

Worldwide Shipping

30 Day Guarantee

Secure Checkout